WK LED Cabin Light Install

Image 3 of 35

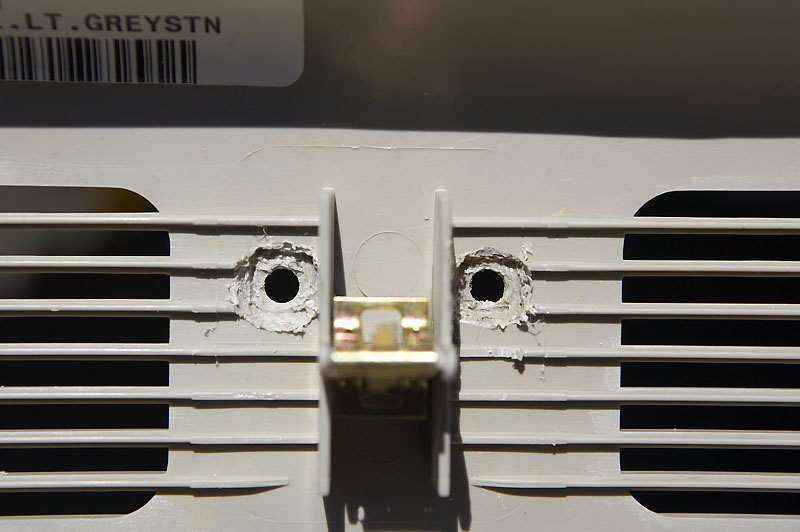

I counter sunk my LED's into the plastic so they'd poke out a bit. It's a time consuming process and there's no real easy way to do it without specialized tools. A Dremel with a small grinding stone might work out really well, but I don't have one. After drilling the holes, used a 3/8 reamer (the largest I had and has a flatter cut to it than a normal drill bit) to get down a bit, then used a large drill bit (27/64 as it is the distance corner to corner of the square part of the LED) by hand to grind away some more. Then I used a soldering iron to melt a square, pushing the excess plastic towards the middle where I would use the large drill again to clean that out. Dry fit and repeat as necessary. WARNING: Using a soldering iron for this will screw up your tip, possibly beyond repair and will also release toxic fumes. I have a spare tip that I use for this kind of thing myself. Also, be very careful not to go all the way through. Realize that the pastic is only a few millimeters thick.